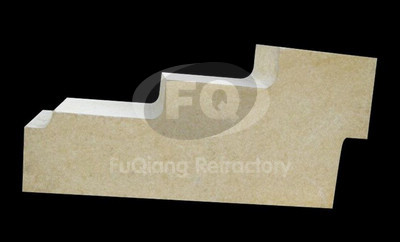

High Alumina Brick

Product Description:

High Alumina Bricks refer to the bricks that contain more than 45 percent alumina (Al2O3). The raw materials for such fire brick are industrial alumina and electrolytically produced corundum, with the addition of refractory clay, as well as rock that has a high alumina content (cyanite, andalusite, diaspore, bauxite, and others). High-alumina refractory bricks are pressed from powders as coarse as 3mm under a pressure of 60-120 meganewtons per sq m (600-1,200 kilograms-force per sq cm) and are fired at a temperature of 1500°-1750° C.

High-alumina refractory bricks are used for walling thermal units (having temperatures higher than 1300°-1400° C) in blast furnaces, air heaters, and chemical reactors.

Technical Parameters:

High Alumina Bricks refer to the bricks that contain more than 45 percent alumina (Al2O3). The raw materials for such fire brick are industrial alumina and electrolytically produced corundum, with the addition of refractory clay, as well as rock that has a high alumina content (cyanite, andalusite, diaspore, bauxite, and others). High-alumina refractory bricks are pressed from powders as coarse as 3mm under a pressure of 60-120 meganewtons per sq m (600-1,200 kilograms-force per sq cm) and are fired at a temperature of 1500°-1750° C.

High-alumina refractory bricks are used for walling thermal units (having temperatures higher than 1300°-1400° C) in blast furnaces, air heaters, and chemical reactors.

Technical Parameters:

|

Items

|

LZ-80

|

LZ-75

|

LZ-65

|

|

AL2O3% ≥

|

80

|

75

|

70

|

|

Fe2O3% ≤

|

1.50

|

1.50

|

1.0

|

|

Apparent Porosity

% ≤ |

18-22

|

19-23

|

20-24

|

|

Bulk Density

g/cm3 |

2.80

|

2.70

|

2.65

|

|

Refractoriness

℃ ≥ |

1790

|

1790

|

1790

|

|

CCS MPa ≥

|

75

|

80

|

50

|

|

Refractoriness Under Load

℃ ≥ |

1550

|

1520

|

1500

|

|

Reheating Linear Change % (℃×h)

|

0~+0.3

1500×2 |

0~-0.3

1500×2 |

0.10~-0.20

1500×2 |

|

Property

|

It has merits like high refractoriness, high strength, fine heat stabilization resist-eroding resisting alkali or sour and so on.

|

||

|

Usage

|

Used in blast furnace, electric stores, hot blast stores, refine furnaces, glass industry and so on.

|

||

Previous: Corundum Brick

Your Contact Details To Us

(*)Required information

Tel: 0086 -0371- 64156592 / 64156599

Tel: 0086 -0371- 64156592 / 64156599